Bâtiment

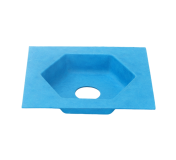

Automobile Stamping Mould

Prix : 10,00 €

The high quality Automotive stamping dies by Kinsrun a professional mould maker in Shenzhen ChinaThe Metal Stamping Process and TechniquesDies are used in a punch press machine to reshape metal, i.e., coin, punch, form, or bend the part. The stamping process and therefore the type of stamping die is determined by the degree of accuracy required; whether processes can be combined for efficiency; and the volume of production required from the die.We can process various knids of stamping dies according to your requirement, if you have drawing in hand, please feel free to contact with us, and we will be happy to working with you!Step 1Quotation3D drawing ,2D drawing or samples is needed.Step 2Payment40% deposit by T/TStep 3Mold DesignMold design for confirmation will be sent within 3~7 days after receiving mold chargeStep 4Paymentanother 30% deposit by T/T after mold design confirmationStep 5Mold MakingMold will be gotten down to production after 70% paymentStep 6Mold TestingMold testing after mold finished and get samplesStep 7Sample confirmationSamples will be sent for approvalStep 8(Mold Modification)If the samples is not approved,we will modify the mold for free and send samples to you again until samples are approval.Step 9Payment & Mold Delivery30% balance by T/T Mold will be delivered in 3 working days after samples approvedStep 10After-sales serviceAfter-sales service will be provided in 24hrs if requested.Kinsrun MouldingTechnology was found in 1997, based in Shenzhen and Foshan city China. After years of steady development has become to a professional full range solutions provider in the field of moulds, has a strong mould design and manufacturing capabilities. Mainly for the industry customers of automotive, home appliances, medical device etc.What we can do?Provide mould design, mould manufacturing, injection molding, metal stamping and casting parts processing, prototyping, end-assembly and other integrated services.Quality assurance: Kinsrun is an ISO9001, TS16949 and ISO14001 certified enterprise. We have advanced inspection instrument and equipment. Meanwhile, we conduct a strict Quality control procedure. This way guarantee every stage from designing, manufacturing to processing always good quality in control. PPAP (Production Part Approval Process) SPC (Statistical Process Control) ISIR (Initial Sample Inspection Report) APQP (Advanced Product Quality Planning) Capability StudiesAppliance: As an experienced mold manufacturer, Our products mainly apply for the following areas: Automobile: Auto interior plastic case, Auto lamp, Instrument panel, plastic auto connectors.Electronic: Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards,USB housing, Mobilephone plastic part, remote control, key-press;Mechanical: Junction box, Motor support plastic part, Pump plastic part, mower plastic parts;Household: Fashion cup, Juice cup, 5 Gallon bottle cap, bottle with screw cap, safety helmet plastic parts;Med ical: Medical instrument body plastic parts, hearing aids,Hollow fiber Dialyzer, Blood-Pressure meter,Sta pler;CNC Machining: various aluminum products, CNC machining;CNC turning;CNC milling;CNC cutting;Stamping parts: Stamping die connectors, metal stamping parts, terminals, pins, shielding case, lead frames, small hardware products.Mould spare parts: High precision mold core.We do best : Factory Price + High precision + Good quality + Fast Delivery Time url: http://www.kinsrun-molds.com Localisation : Building 86, Mashantou 5th.Industry Park, Gongming Town, Guangming New District, Shenzhen City, Guangdong Province, P.R. China., 518000 Shenzhen,

Personne à contacter : lu Richar, 86 755 29921716

Inscrit le 01 septembre 2016

Numéro d'identification de la société : 999

Bonne affaire : acheter au vendeur

Consultez notre guide pour effectuer une transaction en toute sécurité ! En aucun cas Algomtl ne peut être tenu responsable des annonces publiées. Seule la responsabilité du vendeur ou de l'acheteur en cas de litige est engagée. Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

Cette page concerne les importateurs et exportateurs de

Automobile Stamping Mould

Rechercher dans la catégorie : Bâtiment

Rechercher dans la catégorie :

stamping, mould, automobile

|

Thursday 15 September 2022

Beauty Products Bagasse Pulp Insert Recyclable Cosmetics Packaging Products Description Item Name Effective Paper Pulp Packaging Inserts Feature Recycle; Effective; Brand Enhancing; Economic; High Quality Material Recycled pulp; Sugarcane Bagasse Size Customized Color...

- 200000 - Shanghai

- +84(274)3899355

Tuesday 23 December 2025

Quantité : 5 - Prix : $ 3000

Products Pro-Lam 244WF 44 inch Wide Format Roll Mounting Laminator with Stand at Harisefendi provide a 100% money back guarantee and 100% safe, Because Harisefendi the best of the best.We sell some of the best brands such as MIMAKI, ROLAND, MUTOH, SUMMA, SPECTRA, RICOH, SEIKO, U-MARQ...

- 20132 - Medan

- 081283202523

Saturday 06 August 2022

Overview Quick Details Brand Name: OEM Material: Bagasse Pulp, pulp, bagasse pulp, bamboo pulp, straw pulp Model Number: HC-P001 Place of Origin: Binh Duong, Vietnam Industrial Use: Grocery Application: packaging insert Feature: Biodegradable Eco-friendly Size: customized Color...

- 200000 - Shanghai

- +84(274)3899355

|