|

||||||||||||||||||||||||||

|

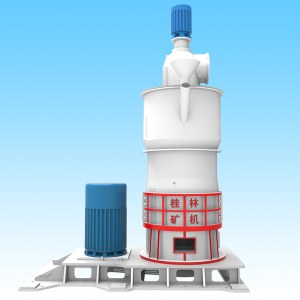

Biens d'équipement

Ultrafine Mill

|

||||||||||||||||||||||||||

|

Item |

GKH1032D |

|

|

Power(KW) |

Main unit(mill) |

132 |

|

Classifier |

30 |

|

|

Fan |

90 |

|

|

Roller layer |

4 |

|

|

Roller QTY(pcs) |

32 |

|

|

output size(um) |

3-35 |

|

|

Capacity(kg/h)(for different output size) |

800-5000 |

|

|

Weight of main unit(mill) |

14.2 |

|

The ultrafine mill is mainly used for crushing equipment for metallurgy, building materials, chemical industry, mining and other mineral materials.

The grinding range of the ultrafine mill is a variety of non flammable and explosive mineral materials, such as quartz, feldspar, porcelain clay, clay, bentonite, calcite, barite, fluorite, ball clay, white mud, gypsum and so on, the Moh's hardness of which is below 7 level and the humidity of which is below 6%. The size range of the finished product by the mill is about 325 mesh -1800 mesh (the size can be adjusted according to different requirements).

The Characteristics of the Ultrafine Mill

The noise and the vibration are small;

The pressure is heavy and the fine powder is much;

The attrition of the grinding ring and grinding roller are both even. They have long service life, which is 3-5 times than that of the ordinary Raymond mill;

It is suitable for processing hard material;

The iron content in the micro powder is low;

It can be operated continuously without affecting the oil injection in the grinding roller bearing house of the mill;

It has small power consumption, high efficiency, and easy installation and maintenance;

There is scraper feeding in the mill, so the production efficiency is greatly improved.

The Application ranges of the Ultrafine Mill

Centrifugal ultrafine mill is mainly suitable for processing the barite, calcite, limestone, kaolin, bentonite, marble, gypsum, refractory material, quartz stone, glass, ceramics and others minerals of high fine powder, the hardness of which is less than 9.3 level and the humidity of which is less than 6%. The grain size is about 80mesh -1500 mesh (the size can be adjusted according to different requirements).

The Technical Advantage of the Ultrafine Mill

The utilization rate of wear materials is high, which is four times the service life of Raymond mill;

The processing of fine sand is more effective than other mills;

It is a kind of high-efficiency equipment for power plant desulphurization;

It can be used to grind before ball milling, the milling efficiency can be increased by 50%;

It is mainly used for all kinds of brittle materials that can be crushed, and the hardness is less than that of Mori's hardness 9 level.

The Comprehensive Characteristics of the Ultrafine Mill

high efficiency. Under the circumstance of the same product size, the output is 40% higher than that of other mills;

The utilization rate of the vulnerable parts is high. When the material and finished product have the same particle size, the service life of the wearing parts is longer than that of other mining machinery;

High safety and reliability. The mill is designed rigorously, and there is no problem of screw loosening and destroying the machine;

Clean and environmental. The use of pulse dust remover and muffler reduces dust pollution and noise. So it achieves national environmental standards.

Personne à contacter : Zeng Ralap , 0773 6812095

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Ultrafine Mill Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : mill, ultrafine |

Thursday 31 December 2009

Quantité : 500 kg - Prix : FOB USD 3.11/kg

Guar Gum is a white to yellowish white powder. It is nearly odourless. Dissolved in hot or cold water guar gum forms a paste of high viscosity. Guar's viscosity is a function of temperature, time and concentration.Localisation : 202 Kesri Nandan Square, Nr. Amba Nagar Canal Road,...

N. B. ENTERPRISE

- nbenterprise

- 395002 - Surat

- 00919925781706

Thursday 23 August 2007

Quantité : 10 - Prix : 3 150,00 €

We have been enjoying a great reputation for providing consistently high quality and original brand new in box of projector, competitive price, and comprehensive service. Full service include delivery, setup, strike, and return services, providing our clients with an absolutely worry...

Office Projector, Co

- officepro

- 3013 - Bandar Seri Begawan

- (673) 2 330 125

Tuesday 17 February 2026

Quantité : 10000

1. Material: Nylon 90%, Spandex 10%. 2. There is rose pattern in the front of underpants. Beautiful and fashion. 3. It is not allergic when you are wearing it. 4. Size: S,M,L,XL,XXL 5. Style: Low, Medium and High waist. 6. Material option: Cooling material, Bamboo Charcoal material...

YSI INTERNATIONAL Co., Ltd.

- grand5588

- 54559 - Nantou

- 886 492932120