|

|||||||||||||||||||||||||||

|

Pro / B2B

Automotive Product Mould

|

|

Part material |

PBT |

|

Cavity |

1 |

|

Tool Accuracy |

+ / - 0.02mm |

|

Mould steel |

738H |

|

Mould steel |

1.1730 |

|

Mould life |

30W |

|

Mould standard |

HASCO |

|

Mould structure |

1 slide |

|

Exporting country |

Italy |

|

Leadtime |

6 weeks |

|

Mould quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

How does Automotive Product Mould Work?

The process cycle of automotive plastic injection mold making itself includes the following steps:

1.Place the mold into the automotive injection molding machine. An injection molding machine is used to close the mold during automotive plastic injection molding by means of a clamp.

2.The granule or pellet-shaped plastic is fed into the automotive injection molding machine.

3.Then the machine heats the plastic until it becomes a liquid. The automotive plastic injection molding machine nozzle then pours the melted plastic into the mold.

4.At this point the mold cavity is filled with plastic liquid. The liquid cools to form a solid product.

5.Finally, the ejector (linked to the ejector system) removes the cooled product from the machine into finished parts.

Personne à contacter : Kevin Shaw, 0086 0769 8535 7333

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Automotive Product Mould Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : product, mould, automotive |

Monday 21 January 2008

Quantité : Pieces - Prix : Call for pricing

International norms, In conformity with CE Norms and produced under ISO 9001: 2000 QMS Fully Microprocessor Controlled 12 Shelves for 12 Different Products Large illuminated advertisement/product display panel Coin Operated Can be configured for 16 Different Coins Compatible to all...

ELEKTRAL AS.

- elektral

- 35620 - Cigli

- +90 232 3767300

Thursday 25 February 2016

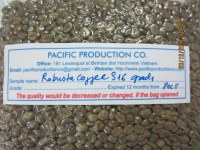

Robusta is easier to care for and has a greater crop yield than the other major species of coffee, Coffea arabica, and, because of this, is cheaper to produce. Robusta Coffee S16 On sieve screen : 90% min. Moisture : 12.5% max. Foreign Matter : 0.5% max. Black and broken : 2% max...

Pacific Production Co., Ltd

- 460000 - Ho Chi Minh

- +84 9 94 85 84 44

Wednesday 15 July 2015

PE Stretch Films Stretch film is a commonly used name for multi-layer (3 to 5 Layered) elastic polyethylene film which it's main raw material is Linear low density polyethylene (LLDPE). Stretch film is used primarily for packing and protection of products, ranging from loads bundled...

Atlas Pars

- 1954966313 - Tehran

- +982126150173

- +989126882335