|

|||||||||||

|

Divers

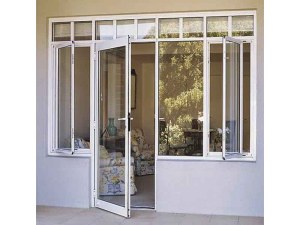

Aluminium Window Profiles

|

|

Alloy |

Standard |

Surface Treatment |

Further Process |

Certificate |

|

6005 T5/T6, 6060 T5/T6, 6061 T4/T6, 6063 T5/T6, 6463 T5/T6, 6082 T5/T6, etc. |

GB 5237-2008, JISH, AAMA, GB, BS, En |

Mill finish, Powder Coating, Anodizing, Wooden grain, Electrophoresis, PVDF Painting, Sanding blasting, Polishing, etc. |

Drilling, Bending, Welding, Precise cutting, Punching, Fabrication of finished products, etc. |

CE, DNV, TUV, ISO9001 |

Why Choose Aluminium Windows Profiles

Aluminum window frames are cost-effective, sturdy and durable, while at the same time having functionality and versatility as well as a stylish modern style.

Aluminum window profiles provide highly durable and cost-effective solutions for residential and commercial buildings. They require almost no maintenance, can be used for life, will not rust, and even have a high corrosion resistance limit.

Aluminum window profiles can be provided in standard sizes, and can also be manufactured in customized sizes and styles to meet your specific requirements.

It is also nice to know that your aluminum alloy window frame can be equipped with various types of functional glass. This includes safety protective glass, aesthetic glass, soundproof glass, fireproof glass and bulletproof glass. They can also be double-glazed to provide higher energy efficiency, better acoustics and many other benefits, bringing comfort and security to your house.

The Production Process of Aluminum Window Profile

1. Ingot casting

The process contains the ingredients, melting, casting, homogenization. This is the main process of certain chemical composition and size of the ingot.

2. Extrusion

Extrusion includes an automatic production line composed of ingot heating, extrusion, cooling, straightening, cutting and other processes.

The ingot heating temperature is controlled at 400℃~520℃, too high or too low will directly affect the extrusion.

3. Heat treatment

Through different systems for quenching and aging treatment to obtain the mechanical properties of the profile. Aluminum profile aluminum windows provide materials in RCS state, that is, high temperature heat treatment and rapid cooling are performed after molding and artificial aging.

4. Surface treatment

The most common steps are anodizing, electrophoresis, powder coatings and fluorocarbon coatings so that the surface can have different colors and good appearance. Surface treatment can enhance the aesthetic appearance of the profile and prolong the service life of the aluminum window profile.

Otalum, as an excellent aluminium section factory, offers a wide range of aluminium profile for you to choose from.

Personne à contacter : Xie Oscar , 86 13613060162

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Aluminium Window Profiles Rechercher dans la catégorie : Divers Rechercher dans la catégorie : window, aluminium, profiles |

Saturday 11 July 2015

Quantité : 1 - Prix : $3,429.00

Truly affordable. Remarkably versatile. With the VersaStudio, we've taken everything that makes a Roland printer great and packed it into one powerful, profit-producing package. Award-winning mild solvent inks. Your choice of media. One device that can print and cut an incredible...

Asia Toner Inc

- 12950 - Jakarta

- 6281361223405

Tuesday 03 March 2026

High Speed Round Bottle Labeling Machine Model No.: LR-450S Labeling Machine LR-450s is featuring for high speed labeling on round labeling or side labeling application. It is widely applied into cosmetic, pharmaceutical, food industry. FEATURES: - Servo Motor Driven / Max Labeling...

Autopack Co.,Ltd

- autopacker

- 33454 - Taoyuan City

- +88 6 33 68 98 06

Saturday 18 October 2014

Quantité : No Limit - Prix : 200 USD

Level 10 is a professional scooter parts manufacturer and supplier in Taiwan. We specialized in manufacturing scooter parts with high quality and competitive price to meet customer's needs. The scooter reed valve kit has good inlet result and increase the hosepower. Model:scooter...

Pai Weih Enterprise Co., Ltd.

- level10

- 71043 - Tainan

- +88 6 62 33 78 28