Billet Shape Measurement and Quality Cut-to-Length System

Billet Shape Measurement and Quality Cut-to-Length System

Overview

The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process.

The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system.

The measuring principle of the system

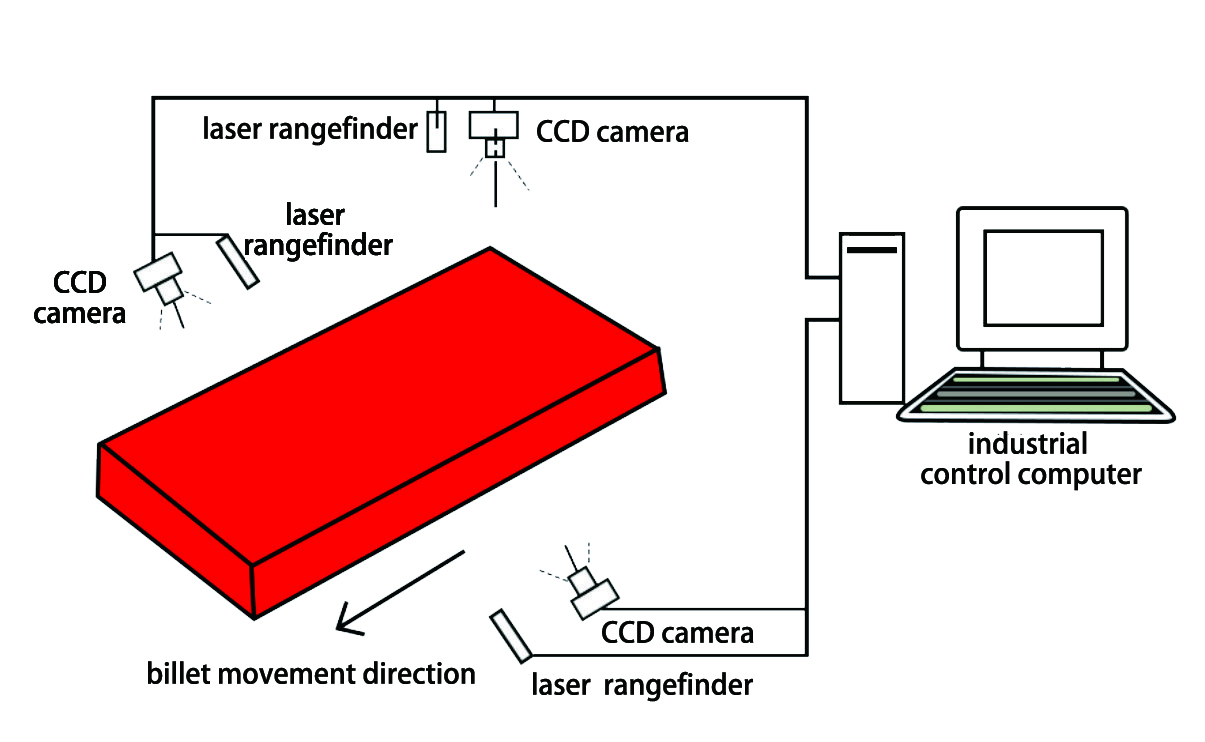

On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products' shape. Through accurate cast products' shape monitoring, the billet thermal expansion coefficient of cast products and cast products' density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length.

The features of the equipment

The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness.

1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc.

2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements.

3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰.

4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding.

5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters.

6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length.

7. Historical cutting data is automatically stored, and the system can set rules for historical data.

8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose.

9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology.

10. The system provides abundant interfaces, which can communicate with the PLC control.

11. Applicable to all kinds of continuous casting machine flame cutting system.

12. Provide automatic, upper and manual cutting control.

The main technical requirements

1. Width range of the inspected cast product: 120~2000 mm

2. Length range of the inspected cast product: 1000~20000 mm

3. Thickness range of the inspected cast product: 35~400 mm

4. Steel plate moving speed: < 3.5 m/s

5. Temperature of the measured steel plate: 0~850 °C

6. Measurement accuracy: width ±0.5mm

Thickness ±0.2mm

Length ±0.2mm

7. Weight calculation accuracy: 1.2‰ (temperature model verification)

Personne à contacter : Floria Liang, 8613995588597

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Billet Shape Measurement and Quality Cut-to-Length System Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : measurement, shape, length, billet, system, quality |

Tuesday 14 July 2015

Quantité : 15000MT - Prix : 2500euro

Meilleur prix Scrap chaude cuivre de vente déchets métalliques / cuivre, ferraille fil de cuivre, baie Copper Mill 99,9% ((Fabricant) Nous sommes des fournisseurs de haute qualité fil de cuivre Scrap 99,99% Milberry spécification Fil de cuivre SCRAP, (Millberry) 99,78% à une pureté de 99...)

CA PRODUCTS CO, LTD

- 10110 - bangkok

- +66 2 62 61 74 11

- +66 9 62 91 74 69

Thursday 30 April 2009

Quantité : 1 to 5 ton - Prix : 2.4$/kg

Indian groundnuts are available in different varieties: like, java, bold, inshell, Blanched and redskin Groundnut kernels and have a rich nutty flavour, sweet taste, crunchy texture and a relatively longer shelf life HPS GROUNDNUT KERNELS TYPE COUNTS PER OUNCE SPECIFICATIONS BOLD 35/40...

valamm uniiversal traders

- valamm

- 600063 - chennai

- 04171 242043

- +919962071628

Saturday 18 October 2008

Quantité : 2000 Tonne - Prix : 4 €

L’Huilerie Anis propose une huile d’olive 100% Naturelle extra vierge de haut de gamme (acidité inférieure à 0,3%) en cours de certification BIO par l'organisme Ecocert. Nous avons décroché en Mars 2007 à New York, la grande médaille d’or et le prix international Quality Summit Award...

Huilerie ANIS

- lesoleildecarthage

- - Nîmes

Paiement sécurisé