Family Mould

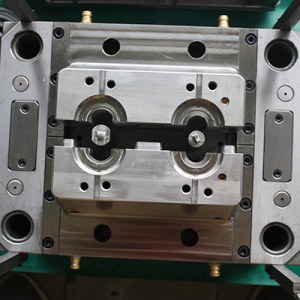

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family tool injection molding have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in the same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

Personne à contacter : Yoyo Tang, 86 13798257041

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Family Mould Rechercher dans la catégorie : Habillement / Mode Rechercher dans la catégorie : family, mould |

Tuesday 06 January 2026

Quantité : 10.000 - Prix : 1500 a 1600$mt

We are able to supply the best quality frozen food products worldwide. Our prices are very competitive and are the best you can find. We spend our time in understanding our customers need and we have the skills and ability to meet every customer's specific requirement. With a skill...

IRAN Trade

- ogfrance

- 93201 - Tehran

- +33 7 62 58 79 19

Saturday 27 June 2015

Quantité : 200 - Prix : 3€30

Bonjour, A la vente, Baton perche pour SELFIE. Différente couleur de manche. Attention, certains téléphone Android n'ont pas la fonction "baton selfie" dans les paramêtres. Fonctionne avec Iphone 4/5/6 et Samsung S4 et +. 3€80pièce pour un carton de 50. 3€40pièce pour un carton de 100...

Hard Discount 93

- 93420 - Villepinte

- 06 52 93 24 09

Sunday 28 April 2013

EXTINCTEUR-MAXI PROTECTION est une société qui vous propose - Le vente de tout type d'extincteurs (à poudre, CO2, eau pulvérise ... ..) - L'installation de vos matériels contre l'incendie (extincteur, RIA, détecteur de fumée….) ----- ----- ----- ----- ----- ----- ----- ----- ----...

Maxi Protection

- maxisarl

- - Rabat

- 00212537202632

- 00212661343484

Paiement sécurisé