High-quality Rice Husk Briquette Machine On Sale

Rice husk briquette machine can make the rice husk to briquette for further usage. It is a way to recycle the rice husk and make value from the product. Rice husk, another name as rice hull, is a kind of biomass waste as the coat of the rice. The ingredients of it are cellulose (40%-50%), hemicellulose (10%-30%), and lignin(20%-30%). The lignin itself is with a high rate compared to wood (17%-32% for different wood), which makes a good material for briquetting.

Rice Husk Usage

Rice husk is widely used as a wide distribution and high burning value. It is easy to burn, with less pollution and ash content. Burning rice husk can highly reduce the SO₂rate of the exhaust compared to use coal. Mainly the rice husk has several ways to use with its burning effect:

1. Used in daily life as fuel for boiling water and cooking.

2. Used to burn for making clay bricks.

3. Used as fuel for boilers.

4. Used to burn for making electric.

Why Make Rice Husk Briquette

The rice husk can be directly used as fuel, but this makes a lot of heat loss. The bulk burning efficiency for rice husk is only 10%-30%, make rice husk briquette can improve this work. After the rice husk is made to briquette, the burning value then is 60% higher than wood, density is 10 times as the bulk (almost twice as wood). Due to this high density, it can keep on burning for two hours after the flame stops. The briquette also improves the work of storage and reduce the fire risk for the bulk rice husk.

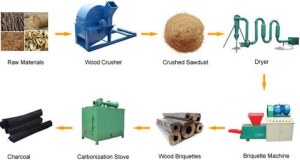

Rice Husk Briquette Plant Process

The rice husk is normally with a length around 7mm which can be briquette by some of the charcoal briquette machine but not all of them. Make it with proper size is crushing. The crushed rice husk with proper moisture then can be briquette in charcoal briquette machine as making the briquette. It's a simple process with several machines.

Raw rice husk ⇒ Drying (dryer) ⇒ Crush (crusher) ⇒ Briquette (briquette making machine) ⇒ Carbonization (carbonization furnace)

If your rice husk briquette plant only with small capacity, you may find your own way of drying like put it in the sunshine. Else we advise using a dryer like rotary drum dryer for this process in order to make the continuous plant, even moisture of the raw husk, and higher the efficiency.

Personne à contacter : Yan Amy, +8615838279423

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de High-quality Rice Husk Briquette Machine On Sale Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : machine, rice, quality, husk, briquette, sale, high |

Saturday 21 February 2009

Quantité : container - Prix : Call

Our safety glasses made of high impact resistance poly carbonate material. Hard coating, anti scratch, anti fog. Our product can comply ANSI, EN, CSA standardLocalisation : road 22, Tan Thuan EPZ, 84-8 district 7, Personne à contacter : Rose Nguyen, 84 8 7701666

Cheng Lih Industrial Co., LTD

- chenglih

- 84-8 - district 7

- 84 8 7701666

- +84 9 55 80 41 17

Sunday 24 August 2008

Prix : fob

we are an italian off-shore firme operating in the textile sector with an italian experience of 25 years we offer a wide range of services: dyeing and finishing cloths for the fashion market. we meet our client 's high expectation by delivering the best service at the compétitif price...

Sunday 07 January 2007

Quantité : ANY

Our ISO 9001:2000 Certified company, is a professional Sheet Metal Small & Medium Pressed Components manufacturing company located at Kirti Nagar, New Delhi. We are actively engaged in manufacturing Press tools, Aluminum Casting Dies, Gasket Cutting Dies & processing sheet metal components...

Dhanjal Engineering Works

- diemakers

- 110015 - New Delhi

- 919811387976

Paiement sécurisé