TIANXIANGHAO STEEL PIPE MACHINE

Stainless steel pipe threading machine is a manufacturing system that is used to produce different types of steel , such as spiral welded , longitudinal welded , seamless , and galvanized . The spiral pipe machine for sale used in the steel pipe production process are designed to form, weld, and shape the steel according to the required specifications and standards. The production of steel is vital for various industries such as oil and gas, water supply, construction, and transportation. Overall, steel china pipe production lines are essential for meeting the demand for high-quality steel in various industries.

TIANXIANGHAO STEEL PIPE MACHINE FOR SALE

Spiral Welded Steel Pipe Production Line

Large Diameter Spiral Welded Pipe Production Line

Small Diameter Spiral Welded Pipe Production Line

Heavy Duty Spiral Welded Pipe Production Line

Thin Wall Spiral Welded Pipe Production Line

Stainless Steel Spiral Welded Pipe Production Line

Steel Pipe Hydrostatic Pressure Testing Machine

Hydrostatic Pressure Testing Machine for Large Diameter Pipe

Hydrostatic Pressure Testing Machine for Small Diameter Pipe

Hydrostatic Pressure Testing Machine for Ultra High Pressure Steel Pipe

Steel Pipe Chamfering Machine

Chamfering Machine for Large Diameter Steel Pipe End

Chamfering Machine for Small Diameter Steel Pipe End

Double Station Chamfering Machine for Steel Pipe

Automatic Steel Pipe Chamfering Machine

High Frenquency Welded Steel Pipe Production Line

High Frenquency Welded Pipe Production Line for Large Diameter Pipe

High Frenquency Welded Pipe Production Line for Small Diameter Pipe

Steel Pipe Delivery Machine

Steel Pipe Conveyor

Steel Pipe Rotating Roller Table

Steel Pipe Puller

Steel Pipe Dropper

Steel Pipe Storage Rack

Anti-corrosion and Insulated Steel Pipe Production Line

3PE Anti-corrosion Steel Pipe Production Line

Plastic Coated Steel Pipe Anti-Corrosion Production Line

Polyethylene (PE) Insulated Steel Pipe Production Line

Steel Pipe Testing & Expanding Machine

Steel Pipe End Expanding Machine

Industrial X Ray Equipment for Steel Pipe Inspection

Ultrasonic Steel Pipe Testing Equipment

Advantages Of Using Steel Pipe Machines

ADVANTAGES OF USING STEEL PIPE MACHINES

Increased precision: Braided pipe machine can produce with high precision and accuracy. The accuracy of the dimensions and thicknesses of the ensures uniformity and consistency, making it easier to install and maintain the .

Efficiency: Steel pipe machines can produce large quantities of in a short amount of time, increasing overall production efficiency. Automated processes help to reduce labor costs and increase output.

Customization: Steel pipe machines can manufacture of various sizes, shapes, and thicknesses, offering flexibility in terms of customization.

Quality: Steel pipe machines ensure that the manufactured are of consistent quality, with no defects or variations. This ensures that the are safe and durable, reducing the need for repairs or replacements.

Sustainability: Automatic steel pipe cutters use efficient, environmentally friendly processes, minimizing waste and improving sustainability. Steel are also highly recyclable, reducing the environmental impact of manufacturing and disposal.

ADVANCEMENTS AND INNOVATIONS IN STEEL PIPE MACHINE TECHNOLOGY

Advancements and innovations in square pipe manufacturing machine and square tube manufacturing machine technology have led to significant improvements in the manufacturing process, resulting in better quality and efficiency. Here are some of the recent advancements and innovations in steel pipe machine technology:

1. CNC technology - With the help of computer numerical control (CNC) technology, pipe production line can be programmed to produce highly precise and complex pipe shapes. This technology reduces the need for manual labor and increases production efficiency.

2. Laser-cutting systems - Laser cutting systems are used to cut and shape with high accuracy and precision. They help to reduce material waste and increase production efficiency.

3. Automation - Automation has become a common feature in steel pipe machines, improving production efficiency and reducing labor costs. Automated robotic systems can complete tasks such as loading and unloading raw materials or finished products.

4. Advanced welding technology - Advanced welding technology of spiral welded pipe production line has been developed to improve the strength and durability of steel . These technologies include plasma welding, TIG/MIG welding, and high-frequency welding.

5. Non-destructive testing - Non-destructive testing technology is used to ensure the quality and consistency of manufactured . These techniques, such as ultrasonic testing or magnetic particle inspection of our ultrasonic pipe inspection equipment, can detect defects and inconsistencies in the production process.

6. Additive manufacturing - 3D printing has been recently explored as a potential alternative method for manufacturing steel . While still in its early stages, this technology has the potential to revolutionize the industry by producing complex in a more efficient and automated way.

Overall, these advancements have revolutionized the steel pipe industry, improving productivity, efficiency, and quality. The industry is likely to continue to invest in these technologies, leading to more innovative manufacturing processes in the future.

THE IMPORTANCE OF QUALITY CONTROL IN STEEL PIPE MANUFACTURING

Quality control is an essential aspect of steel pipe manufacturing. It ensures that the final product meets the required standards and specifications. Quality control helps in maintaining consistency in the manufacturing process, reducing manufacturing costs, and enhancing customer satisfaction. Below are some reasons why quality control is critical in steel pipe manufacturing.

1. Compliance with Standards: Steel are used in various industries, and the required standards may differ from one industry to another. Quality control ensures that the meet the specified standards, preventing issues such as pipe failures, equipment damage, and product recalls.

2. Consistency in Manufacturing: Quality control establishes a consistent manufacturing process, resulting in products of uniform quality. This consistency helps to prevent defects, reduce scrap rates, and increase efficiency.

3. Cost Savings: By preventing defects, quality control can reduce costs associated with production, inspection, and rework. It also helps to minimize the risk of product recalls, thus avoiding significant financial losses.

4. Customer Satisfaction: Quality control ensures that the final product meets customer specifications and expectations. By providing high-quality products, customers are more likely to be satisfied and continue to do business with the manufacturer.

5. Safety: Defective steel can cause significant safety hazards in various industries. Quality control helps to prevent such hazards by ensuring the meet safety standards and are free from defects. In conclusion, quality control is critical in steel pipe manufacturing. It ensures compliance with required standards, establishes consistency in manufacturing, reduces costs, enhances customer satisfaction, and improves safety.

Personne à contacter : txhmachine txhmachine, 0317 6213222

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de TIANXIANGHAO STEEL PIPE MACHINE Rechercher dans la catégorie : Bâtiment Rechercher dans la catégorie : steel, pipe, machine, tianxianghao |

Thursday 11 December 2014

Quantité : 6700 tonne - Prix : 95EUR/TOONES

Cher Monsieur, Nous sommes une entreprise spécialisée dans la fabrication de l'énergie de la biomasse et ses sous - produits. Nous produisons et exportons Granulés bois, Briquettes, Bois de chauffage, charbon de bois, sciure de bois. Nous offrons nos produits à la des prix plus...

commerce

- -

- (36 37) 373 160

Monday 28 December 2015

Quantité : OEM/ODM Se - Prix : OEM/ODM Services

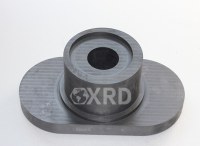

fabrication XRD graphite, situé dans le moyen de la chine, a été la production et la vente de divers produits de plus de 30 years.we graphite ont consacré dans des produits de haute qualité à prix modéré et de courte prestation nous sommes devenus les fournisseurs bien établis à long...

XRD Graphite Manufacturing Co., Ltd

- zcxooo

- 467400 - Pingdingshan

- 86 15516002510

Tuesday 23 December 2025

Quantité : 25 tonnes - Prix : A determiner

CUBITAINERS DE GEL DOUCHE + LIQUIDE VAISSELLE + LAVE-LINGE DE TRES GRANDE MARQUE - SOCIETE ATOUT NEGOCE - destockage, valorisation et réemploi des produits. ENTREPOT: 12 - 14 rue Fresnel ZAI PARIWEST 78310 COIGNIERES- MAUREPAS Port: 06.16.59.07.14 Tél: 09.65.31.82.44 Localisation ...

ATOUT NEGOCE

- lechevrel

- 78310 - COIGNIERES

- 06 16 59 07 14